Benefits of high performance conductors

High Performance Conductors (HPCs) are modern electric conductors (i.e., power lines) made from advanced materials. HPCs replace conventional transmission lines with stronger, lighter, and higher-capacity cables, taking advantage of carbon-fiber and superconducting materials.

When compared to traditional conductors, HPCs have:

Lower or no resistance, providing energy savings

Greater ampacity, providing increased grid capacity, reliability, and resiliency benefits

Lower or no thermal expansion, providing wildfire risk mitigation and grid resiliency benefits

Speed to power: American innovation, leadership, and AI competitiveness

HPCs double to quintuple transmission capacity on existing lines.

Installation takes ~6–18 months, compared to 10-20 years for new lines, meeting AI-driven data center load fast (10-65 GW through 2029).

$1.1 billion+ in recent federal investment supports Advanced Transmission Technologies including HPCs.

Made in the USA: creating Jobs and driving economic growth

AMP members manufacture HPCs and their component parts in states like Texas, California, South Carolina, Pennsylvania, and Massachusetts.

Deployment supports thousands of union jobs in manufacturing, construction, engineering, and grid services.

Safer, more affordable infrastructure for American families and businesses

Annual replacement of 5,000 miles of aging transmission lines with HPCs would enable the integration of roughly 27 GW of additional generation.

$140 billion in potential savings over a decade from HPC energy savings

HPCs reduce line sag, increasing ground clearance by 5–15 feet to improve wildfire safety.

AI, electrification, and reindustrialization are driving massive new demand for firm power.

New lines take a decade to build, but HPCs can be installed on a timescale measured in months.

Deployment options for high performance conductors

Every transmission line has a finite life expectancy, typically 50 to 70 years. Over time, aging infrastructure, extreme weather, and changing system needs make replacement necessary.

Utilities address this through two well-established practices:

Reconductoring is the process of replacing old conductors with new ones, typically reusing the existing towers and rights-of-way.

Rebuilding involves the replacement of the entire line, including conductors, towers, and terminal equipment, either due to aging structures or to support larger, heavier conductors.

These processes are a routine part of utility operations and maintenance. But under the status quo, reconductoring and rebuilding are often done with “like-for-like” replacement, reinstalling the same outdated, steel-core conductor types that limit line capacity and performance.

Instead, we can reconductor or rebuild using High Performance Conductors. Doing so allows utilities to unlock major increases in line capacity, improve reliability and resilience, and reduce losses and costs, all without waiting a decade or more for new transmission lines.

HIGH PERFORMANCE CONDUCTORS SHOULD ALSO BE USED when building NEW TRANSMISSION

In addition to reconductoring and rebuilding existing transmission, HPCs should be deployed when new build is needed. When creating new corridors, HPCs offer planners maximum design flexibility. Their higher ampacity can reduce the size or number of lines required to meet a given capacity target, potentially lowering land acquisition needs and environmental impact.

Deploying high performance conductors is one of the fastest, most cost-effective ways to expand the grid.

High Performance Conductors (HPCs) typically cost 5–10% more when compared to existing, traditional conductors of a similar diameter such as steel-core conductors (ACSR), but that premium enables:

20-80% more efficiency

150-500% increase in the power transfer capacity

Wildfire safety gains from reduced sag and higher clearance

In most cases, this premium is paid back within 1–3 years through lower congestion costs, reduced line losses, and access to cheaper generation. The long-term net benefits of HPCs outweigh short-term costs.

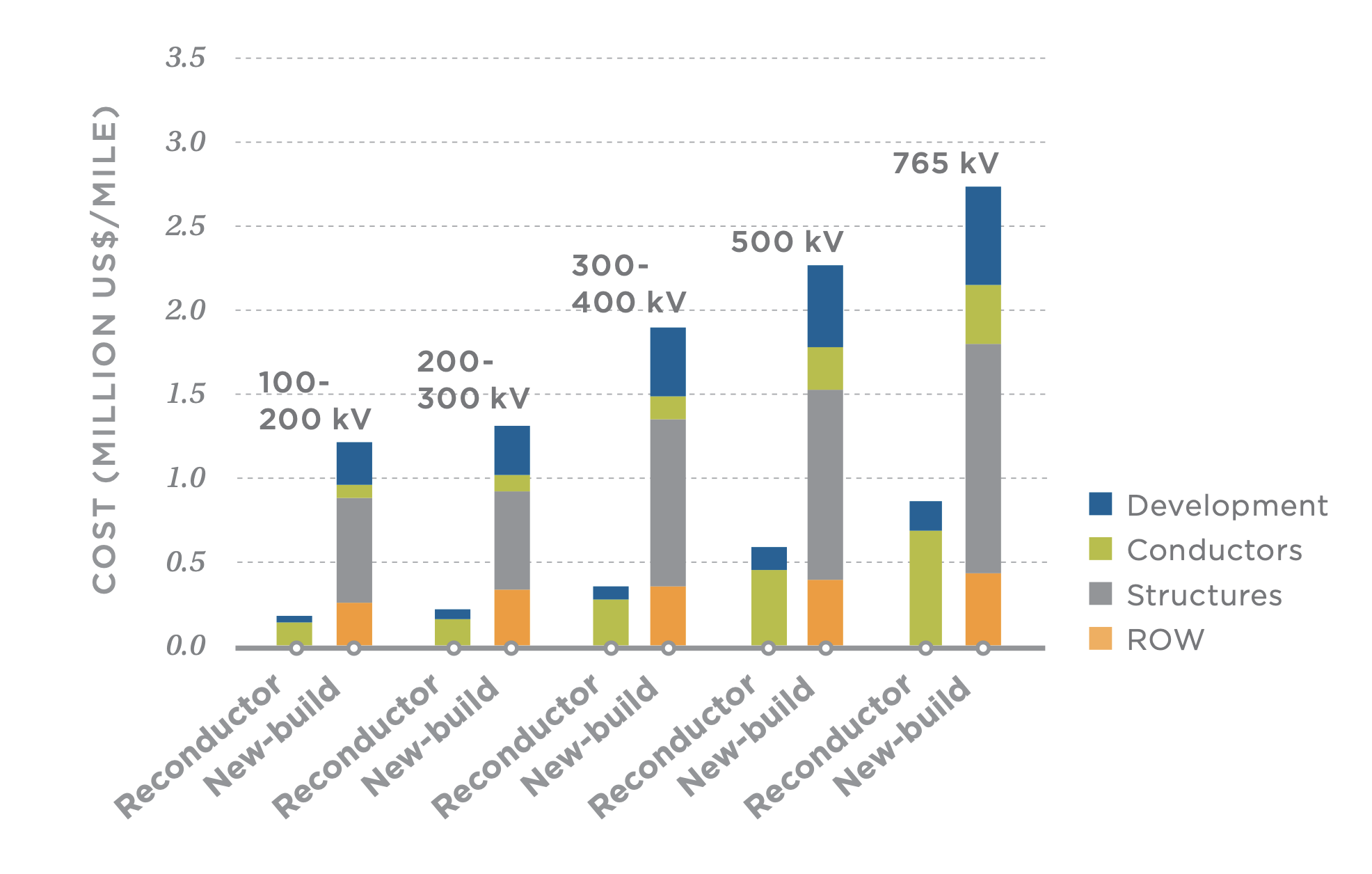

Cost estimates for reconductoring vs. new build (Source: Gridlab)

there are two types of high performance conductors

Carbon CORe

Use advanced materials, such as carbon fiber, to create a core that is lighter and stronger than steel, with just 1/10th the thermal expansion, enabling 150-300% more capacity than traditional steel-core conductors, 20-40% lower line losses, and significantly less thermal sag when strung on towers.

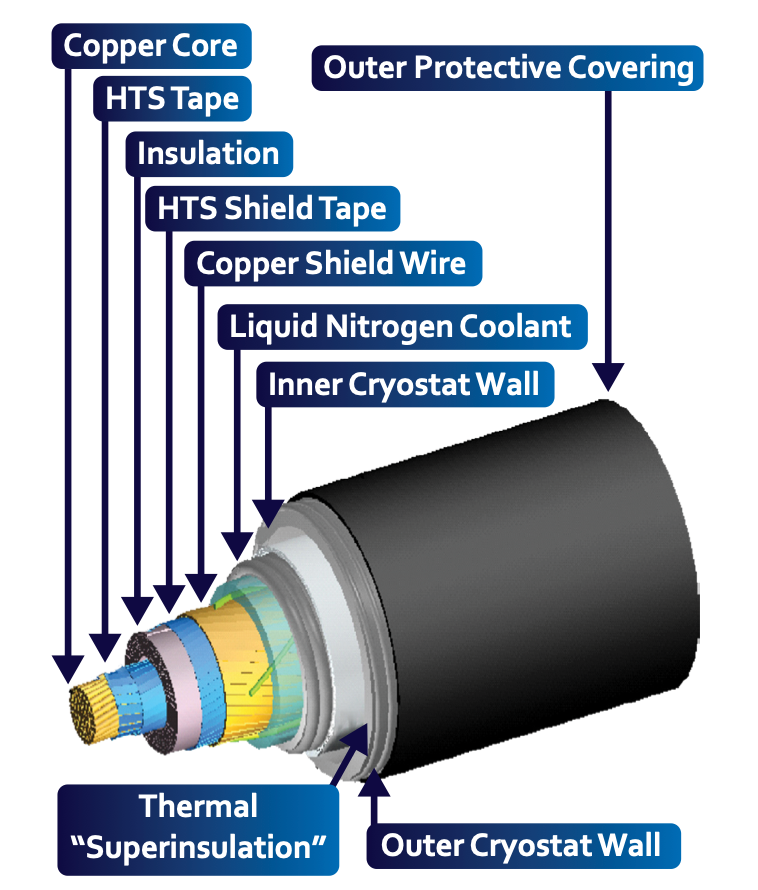

SuperconductorS

Use advanced metallic compounds that become superconducting when cooled with liquid nitrogen, offering nearly zero resistance to enable very low power losses, 5-10x the capacity of traditional steel-core conductors, 80% higher efficiency, and the option to install underground or in compact enclosures.

contact us

Let’s build a stronger grid, together.

The AMP Coalition works with technology providers, utilities, policymakers, and advocates to accelerate deployment of High Performance Conductors.